Key Objective: To enable approved contractors to manage their workforce, health and safety compliance, and allocation of work on a Davidsons site. Plus, provide Davidsons with visibility of contractors and their workers, objective measures of compliance to Health & Safety, behaviour, and quality of workmanship.

“The system continues to evolve and has proved a very powerful tool in assessing the quality of work and behaviour of our contractors and their workers on site. It has helped identify poor workmanship and enabled the individual businesses to address the issues, reducing cost to Davidsons. This in turn has perpetuated a realisation of the quality standards set by Davidsons upon contractors. It has empowered Site Managers and Health & Safety representatives with real-time ID verification and prevented disruptive individuals working on Davidsons sites. From a Health & Safety perspective, it helps us benchmark contractors and where required, educate those willing to change and remove those who are not.”

Ross Baylis, Health, Safety & Environmental Director, Davidsons Developments

Davidsons Homes is a family owned and managed company, with over three generations of experience, knowledge and success in homebuilding. With an unwavering dedication to quality, Davidsons Homes has an unrivalled reputation as one of the country’s leading housebuilders and place makers.

Issues: Managing thousands of sub-contractors across dozens of developments involves a lot of risk.

On a busy site the control over who is onsite is critical to health and safety compliance.

• Are the individuals deployed to site by the sub-contractor employed by them, or sub-contracting?

• Have they signed up to both the sub-contractors RAMS, and the Davidsons RAMS?

• Are the qualified to use the equipment?

• When working on site, have they been signed in?

• Have they had a site induction?

• Have they been briefed of site activities they need to be aware of that day?

• Have they signed out?

Where contractors work on multiple sites, managing the quality of their work is essential to maintain the highest standards.

• What’s the quality of their work?

• Do their workers behave professionally and respectfully on site?

• What’s their health and safety compliance record?

Understanding many contractors didn’t have the systems to manage this information, meant Davidsons had to create an interface which helped sub-contractors manage their employees. It needed to give them visibility on an individual’s performance, as well their company in relation to working with Davidsons.

Tackling tricky issues

If an individual acted in a dangerous or anti-social way, they could be yellow carded, meaning their behaviour was highlighted for a specified period. If extremely dangerous, or repeatedly anti-social, they would be barred from working on a Davidsons site. The challenge was if their employer moved them around, other site managers would not necessarily be aware of their yellow card or ban. Alternatively, if a banned individual changed employer, their new employer would not know they were barred from working for Davidsons.

The elephant in the room

The greatest challenge identified when reviewing the project scope, was how would we get the contractors to use the system and manage their people, at a time of a booming construction market.

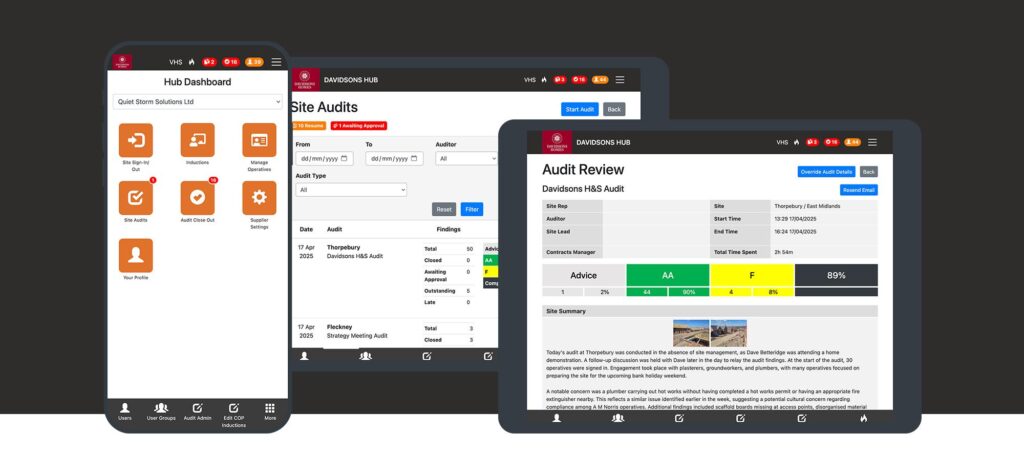

Resolution: The scope outlined all the issues identified and they were mapped out against the current VISION functionality to capture integration and document how the integration would work. This was then storyboarded out in wireframes to make sure the process felt ‘cash machine simple’ as we needed to minimise the resistance to adoption. With the system built in a phased approach, the functionality deemed as essential was documented for release in phase 1 and other functionality was prioritised so the development could be worked to an agile methodology.

Testing and pilot

With the first phase complete, the system was in test and the project team were considering how we would incentivise the contractor database to engage. The first step was to work with companies identified as forward thinking, tech savvy and who wanted to work smarter. These were onboarded and the trials began. On the whole the feedback on the system was it was easy to use, a few minor tweaks, and we were ready to roll-out – this was December 2019. We wouldn’t know it yet but within the next quarter, this system would enable the business to continue when many construction businesses were figuring out how they would adapt to working through ‘COVID safe working practices’ in lockdown.

Over 4500 individual contractors we added to the system in just over a week

The system was quickly adapted so that the ‘COVID safe working practices’ was added to the login process, in addition to the daily site briefing. This was geotagged, so the system recorded where the individuals were when they signed in and signed out.

• Approved contractors are provided with an Administrator login with which they could:

– Add their RAMS

– Register their employees and sub-contractors (workers)

– Workers CSS card were scanned and uploaded

– Workers relevant qualifications specified, together with expiry dates of relevant certifications

– Workers qualifications approaching expiry date are highlighted to the relevant contractors’ administrator

– Workers logins activated with an email notification

– Sites were allocated to workers, together with the tasks set for that days work

• Workers were provided with a login to undertake their Davidsons Induction and work allocation

– They confirmed their details

– Read and signed up to their employers/contractors RAMS

– Read and signed up to the Davidsons RAMS

– Were allocated a Davidsons site to work at

– Completed a site induction (which was recorded, and only needed to be repeated if it had changed)

– Accessed the tasks for completion at the specified site

• Upon arrival at the site workers signed in on their mobile phones

– They were given the site induction (if not completed previously)

– They were updated upon the potential hazards and activities on site that day/week

• Site Manager

– The Site Manager knew who to expect, and what they were tasked to do, where.

– Qualifications with expired certification flagged up on sign-in, if relevant to tasks, entry denied.

– Anyone turning up unannounced was given instructions to follow and a number to call

– As the CSS card contained a photo of all workers, the site manager had ID verification

– The Site Manager could see disciplinary and Health & Safety violations set against a worker

Quality Performance

• The inspections are triggered by the Build Programme, the audits are logged and photographic reporting/close out evidence uploaded. Any quality issues are linked back to the relevant contractor via the Contractor Hub.

• Any disciplinary actions or Health & Safety violation was documented by the Site Manager and /or Health & Safety inspector, this was logged and assigned against the worker.

• As individuals are assigned to tasks at plot level, any defaults or issues identified at a quality inspection logged, this automatically assigned it against the main contractor, who could identify ‘the worker’ who was assigned.